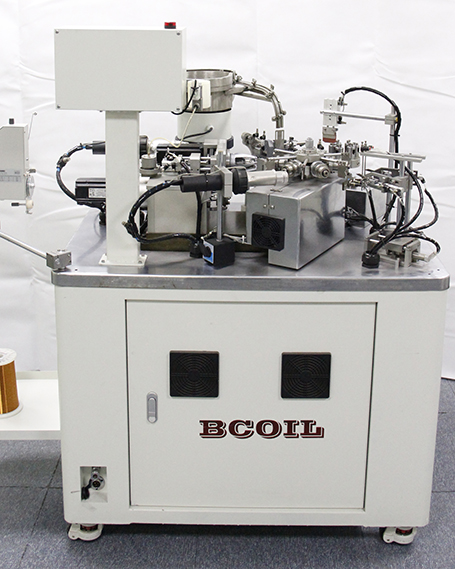

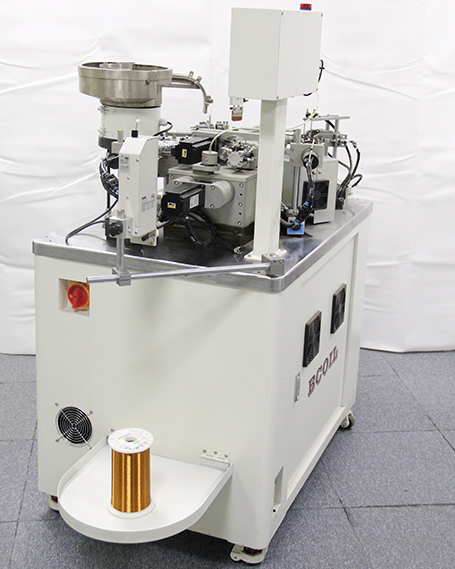

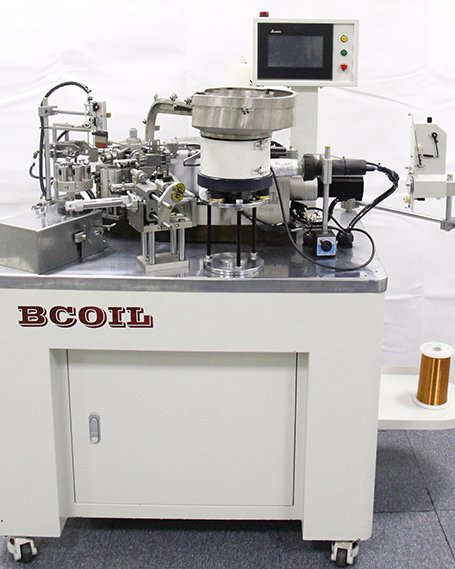

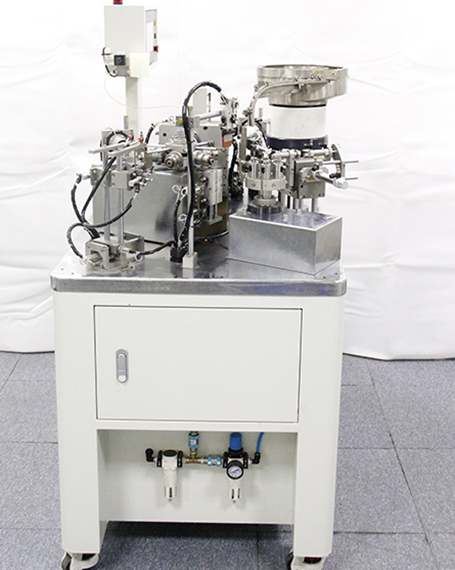

The control system adopts touch screen input, and the parameter setting is simple and easy to understand.

The mechanical structure is designed reasonably, and all materials used are processed by special

technology. The mechanical movement part adopts imported servo motor and high-precision ball screw, and

the rotating part adopts imported bearings to ensure the high efficiency and precision of the product;

The equipment can be efficiently and stably produced 24 hours a day, and one person can operate multiple

equipment. The equipment has high compatibility and can cooperate with the automatic production line.