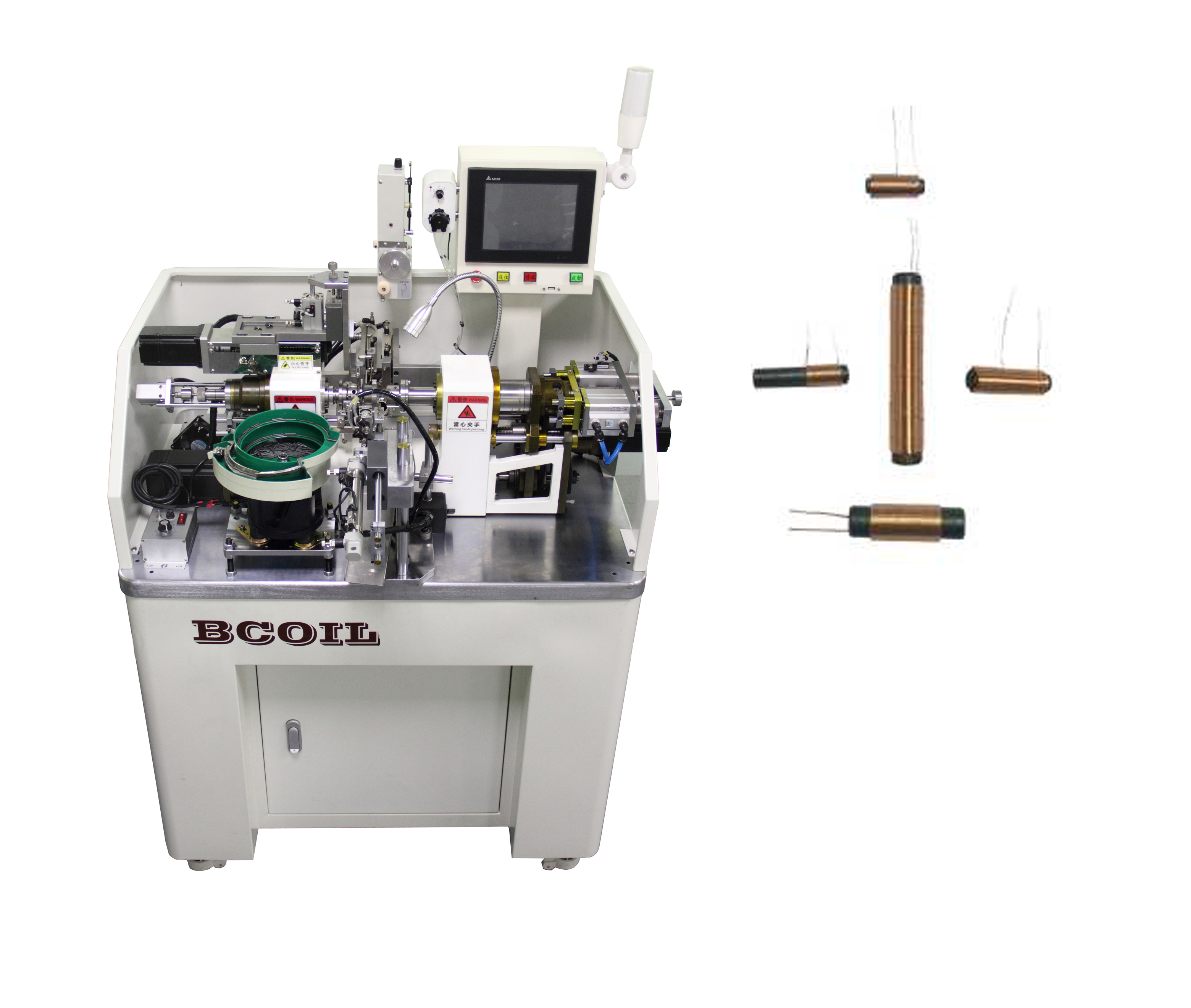

The winding machine is a device for winding a linear object onto a specific workpiece, usually used for winding copper wire. Most electrical products need to be wound with enamelled copper wire (enamelled wire for short) to form an inductive coil, which can be processed in one or more ways with a winding machine.

It can not be ignored that the vibration reduction and dryness reduction of the machinery industry is a proof of the technical strength of the product, which is true of any machinery The winding machine will produce noise during operation, and the noise size has a great correlation with the product life cycle. How to reduce vibration and dryness?

In fact, damping is the most effective way to reduce vibration resonance response The function of damping is to convert vibration energy into heat energy to dissipate, so as to suppress structural vibration and achieve the goal of reducing noise. This processing method is called damping vibration reduction and dryness reduction.

In addition, the vibration reduction and dryness reduction of the winding machine are mainly realized by reducing the strength of the bending vibration of the metal plate The shell structure of automatic winding machine, parallel winding machine and large button force winding machine is generally made of metal sheet. The damping of metal sheet material is very small, and noise is radiated due to vibration during operation.

Apply a layer of damping material on the metal sheet of the winding machine. When the metal sheet experiences bending vibration, the vibration energy will be quickly transferred to the damping material coated on the plate, causing friction between the sheet and the damping material as well as inside the damping material Due to the large internal loss and friction of damping materials, a considerable part of the metal vibration energy is lost and turned into heat energy, which weakens the bending vibration of the thin plate and shortens the vibration time after the thin plate is excited, thus reducing the energy of the metal plate radiated noise. This is the principle of damping vibration reduction and dryness reduction.